BUS STOP OF THE FUTURE

* Click Image to ENLARGE

* Install ADOBE FLASH PLAYER to play the video

* The following is a list of work that I have contributed

------------------------------------------------------------------

PROJECT: BUS STOP

------------------------------------------------------------------

- CONCEPT, DESIGN IDEAS, CONSTRUCTION

- FABRICATE 1:1 MOCK-UP OF THE BUS STOP

- EXHIBITED AS A PART OF SYDNEY DESIGN WEEK

------------------------------------------------------------------

BUS STOP ORIGINAL FILES

------------------------------------------------------------------

Initial Concept

PDF Presentation

Original 3D BUS STOP

------------------------------------------------------------------

AUSTRALIAN STANDARDS

------------------------------------------------------------------

ALTERNATIVES SOLUTION

------------------------------------------------------------------

The design

Use specific precedents and gain information from the Ministry of Transport NSW and any other relative sources, that depict all factors related to the design of a bus stop.

The materials

Ensure materials are cost effective, accessible and be able to be used on the machines in the design lab in the Red Centre, as we must build the 1:1 using the resources in the design lab to cut - cost.

The assembly:

Ensure that we find appropriate connection methods that lock the pieces together in a productive and efficient manner

The time management

Ensure that we decide on what member is doing what within the group and how we can save time and resources in any way.

The budget

Research in-depth the most cost effective resources as we only have a $20,000 budget.

CONSTRUCTION RESEARCH

------------------------------------------------------------------

MiniTec Profile System

Structural Plan

source: http://www.minitecframing.com/

------------------------------------------------------------------

MATERIAL RESEARCH

------------------------------------------------------------------

Marine Plywood

1. High uniform strength - wood is 25-45 times stronger along the grain than across the grain.

2. Freedom from shrinking, swelling and warping - The balanced construction of a plywood panel with the grain direction of adjacent veneers at right angles tends to equalise stress, thus reducing shrinkage, swelling and warping.

3. Non-splitting qualities solid wood splits fairly readily along the grain. Plywood by virtue of the crossed lamination can be nailed or screwed near the edges without damage from splitting.

4. Availability of relatively large sizes - Plywood can be sold in sizes up to 6 ft * 25 ft and by the scarf jointing of small sheets up to 6 ft *40 ft, however 6 ft*3 ft is the most common size.

5. Dense woods can be sliced and bonded into plywood panels for use in furniture construction whereas furniture fabricated from solid timber would be far too heavy.

7. Ease of fabrication of curved surfaces - The trend of modern architectural design is to feature curved surfaces.

8. One of the important aspects in the manufacture of plywood is that it results in the conservation of timber by the elimination of the waste which occurs in sawing e.g. sawdust. Waste is confined to the small core which remains after peeling, and from the veneer which is lost in rounding up the log, and the elimination of such defects as knots and splits.

source: http://www.hafele.com.au/HafeleHome/products/door-systems/

------------------------------------------------------------------

FINAL DESIGN

------------------------------------------------------------------

------------------------------------------------------------------

------------------------------------------------------------------

ILLUSTRATION

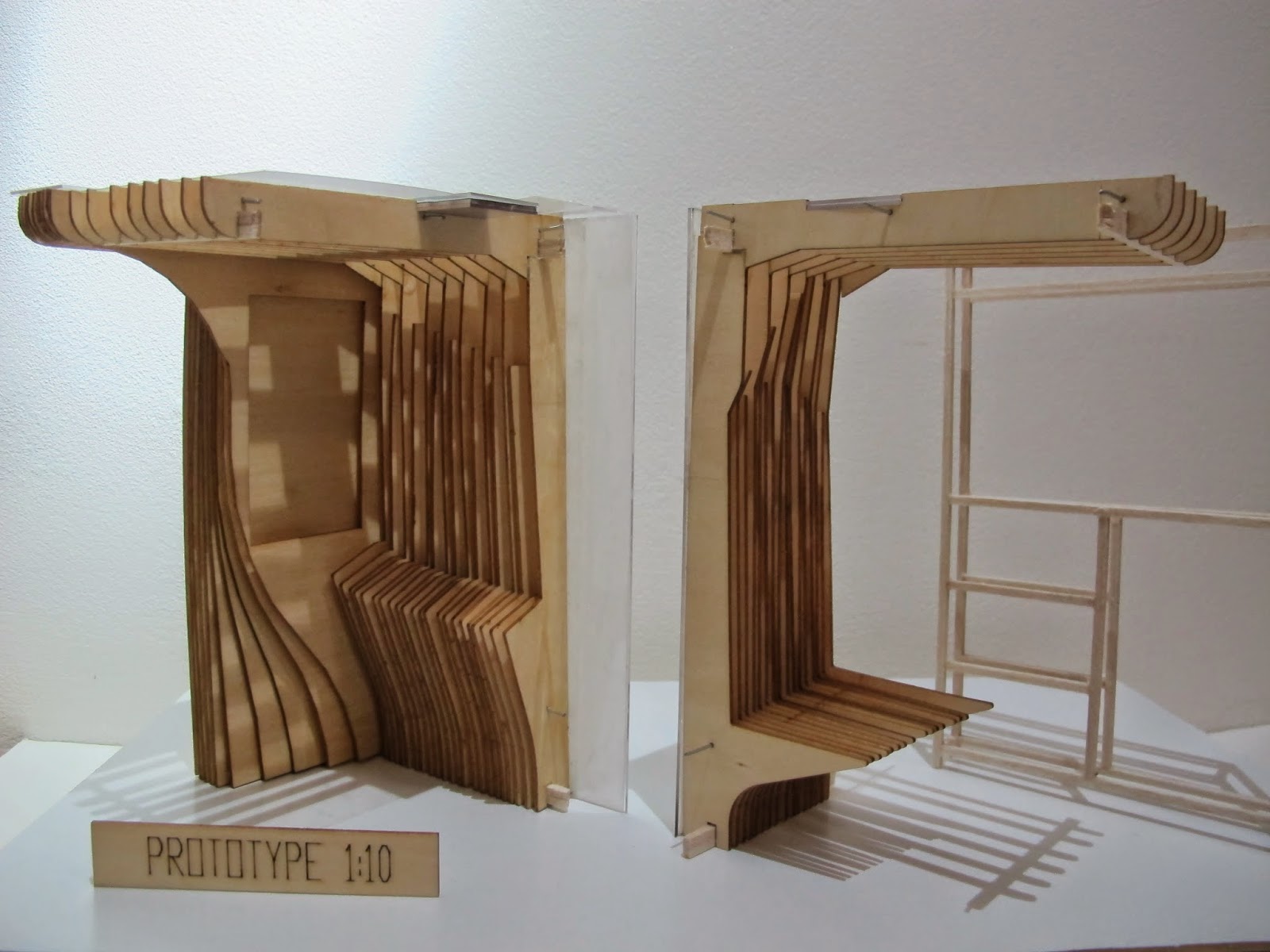

PROTOTYPE

Laser Cut Files

DETAIL DRAWINGS

-----------------------------------------------------------------

Program used: Solidworks, AutoCAD

Contribution: All of the lineweight, all of the hatching, all of the templates, all of the drawing's correction, detail drawing No. 9, 21, 22, printings

------------------------------------------------------------------

PANEL PRESENTATION

------------------------------------------------------------------

VIDEO

-------------------------------------------------------------------

Program used: Adobe Premiere, Sketchup, Photoshop

Contribution: all modelling animations, all footage, all video editing

------------------------------------------------------------------

PRESENTATION 04/06/14

-------------------------------------------------------------------

ARUP Engineer

------------------------------------------------------------------

DOCUMENTATION

------------------------------------------------------------------

------------------------------------------------------------------

.PNG)

.JPG)